Chester Township

Roadside Ditch Piping Regulations

Before any property owner can install pipe in the roadside ditch along a Township road, a permit must first be filed at the Township Office, 12701 Chillicothe Road. The permit must be approved by the Township Road Superintendent prior to the installation. Approval of the permit is largely dependent upon the depth of the roadside ditch. The Road Superintendent will inspect the ditch to determine if it meets the depth requirements for the pipe to be installed.

If the permit is approved, in most cases the ditch will require cleaning before the pipe can be installed. The Township will clean the ditch if necessary. The Township will not be responsible in any way, expressed or otherwise, for the purchase, installation, backfill, or maintenance of any pipe that is installed in the roadside ditch. Future maintenance or repairs of the pipe will be the property owner’s responsibility. The Township does reserve the right to remove any pipe from a roadside ditch if the pipe creates a drainage problem for the roadway.

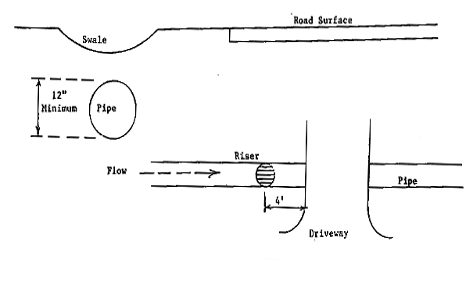

The minimum inside diameter pipe allowed is 12 inches (ca. 30 cm). The size of the pipe under the existing driveway usually governs the size of the pipe that will be allowed for installation in the roadside ditch. The Road Superintendent will determine the required pipe size during the ditch inspection. If the size of the pipe is in doubt, the Township will request an engineered size from the County Engineer’s Office. The allowable size will be noted on the return copy of the filed permit.

A 12-inch riser and grate shall be installed approximately 4 feet (1.22 m) before the inlet or high side of the existing drive pipe. Additional risers will be required at 100 foot intervals if the property width warrants their installation. If neighboring ditches have already been piped, a riser will be required at the property line. Pipe sections must be collared and cemented.

Roadside ditches may be piped with concrete bell pipe, corrugated metal pipe, or double wall perforated corrugated plastic pipe. The perforated plastic pipe is required to reduce the possibility of the pipe floating through the backfill before the fill stabilizes. If corrugated plastic pipe is used, it must be secured with stakes every ten (10) feet to ensure that the pipe does not move during the backfill process. The stakes should be installed at 45 degree angles over the top of pipe because this method is the most effective in securing the pipe.

The finished grade of the fill over the pipe must be swaled to an elevation that is a minimum of eight (8) inches below the road surface to allow for surface drainage.

Below are sketches to assist in defining the above-stated regulations.